-

3 Axle Lpg Gas Tank Semi Trailer

3 Axle Lpg Gas Tank Semi Trailer

-

Low Bed Trailer

Low Bed Trailer

-

SHACMAN F3000 Tractor Truck

SHACMAN F3000 Tractor Truck

-

Flatbed Pillar Trailer

Flatbed Pillar Trailer

SUNSKY VEHICLE, a manufacturer of flatbed semi-trailers, has found that the Flatbed Pillar Trailer i...

The bulk cement tanker trailer is designed to meet the demands of transport bulk cement, powder, ash etc. This model bulk cement tanker trailers supplied by SUNSKY trailer draws on the advantages of similar models at home and abroad, and is manufactured with advanced technology and strict production process manufacturing.

The bulk cement tanker trailers have reasonable structure, reliable performance, beautiful appearance and easy operation. It is suitable for the transportation and pneumatic discharge of powdered dry materials such as fly ash, cement, lime powder, ore powder and other particles with a diameter of less than 0.1mm. The discharge height can reach 15m and the horizontal distance is 5m. The tank adopts single-cone and double-cone inclination horizontal structure, double-tube intake, its discharge speed and remaining rate meet the requirements of industry standards.

This article introduces the structural features, technical performance parameters, operation and use methods and maintenance tips of bulk cement semi-trailers in detail, which can be used and referenced by truck drivers, maintain staff and relevant management personnel on cement transport or cement produce industrial.

Contents

Chapter I: Outside view and drawing of bulk cement tanker trailer

1. Outside View

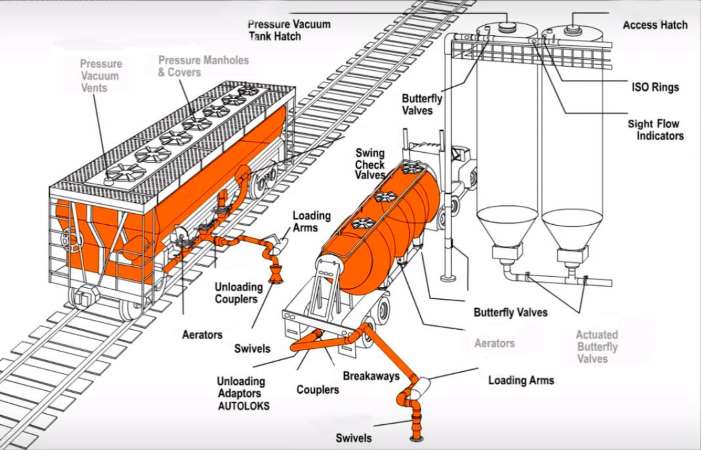

The bulk cement tanker trailer adopts semi-integral structure design. Unit semi-trailer is consisted of tanker body assembly, pipeline system, chassis assembly, suspension system etc.

2. Drawing

① Drawing of 30CBM 2 Axle Bulk Cement Tanker Trailer

② Drawing of 40CBM 3 Axle Bulk Cement Tanker Trailer

Chapter II: Main structure and working principle of bulk cement tanker trailer

1. Bulk Cement Tanker Body Assembly

The bulk cement tanker assembly is consisted of tanker body, inlet, fluidized bed, intake pipe assembly, cleanout port and other pats. The bulk cement tanker use Single compartment and horizontal structure design, which make the gravity of tanker lower, improve the stability of semi-trailers. The tanker body made of 5mm thickness high tensile carbon steel Q345B, the whole trailer has enough strength, good rigidity and pressure endurance.

The tanker body uses single compartments two air chamber structure design. The width of fluidized Bed is suitable and be layout reasonable, it can help to reduce the unloading time efficiently,improve the volume utilization of tanker and make the residual rate lower. There are two manholes (inlets) on the top of tanker, when open the manhole, on one hand, you can load the cement into tanker, on the other hand, it is more convenient for maintain staff to enter. On the bottom of the bulk cement tanker, it normally set up a cleanout port. When remove the flange, you can clean the residual cement thoroughly

Bulk Cement Tanker Assembly

1.Tanker Body 2.Inlet 3. Fluidized Bed

4. Discharge Pipe Assembly 5.Cleanout Port 6. Intake pipe

The bulk cement tanker trailer set up intake pipe on front and rear air chamber; you can Implement functions of open and close separately through ball valve.

The I-beam of bulk cement tanker trailer is made of high-quality 16Mn steel plate. The I-beam is made inclined and fits on the outside of the tanker. The cross beam is close to the bottom of the tanker and connects the I-beam and the tanker body into a whole unit. The structure is reasonable and strength is strong enough.

The suspension system use the two Axles (or 3 axles) balance type spring suspension. The middle of spring suspension installs the quality balance device,if the bulk cement tanker trailer drives on the uneven road, the balance device will adjust the suspension and buffer the chassis.

If you find the rear axle move back or tires wear too much, you should fasten the U bolts and adjust the tie rod, if broken you should change them in time. Always keep the left and right wheelbase of rear axle is the same. Notice to add lubricating oil on suspension balance shaft.

The Axle system is consisted of Wheel, Axle, brake and tires. Normally choose to install Fuwa or BPW brand Axle.

5. Working Principles of bulk cement trailer

The bulk cement tanker trailer use the air compressor to compressed the air and input the compressed air into the fluidization device on bottom of tanker body thought the intake pipe. The pressure inside the tanker reached to certain pressure(about 0.18 MPA), open the unloading valve. The mixture of cement and air is discharged under the pressure difference between the inside and outside of the tanker and enter to the underground container via discharge pipe

Compressed air→Gas pipeline→Fluidization device→Pressure reaches 0.18Mpa→Start unloading

Chapter III: The maintain and operation of bulk cement tanker trailer

1. Run-in period of new bulk cement tanker trailer

The correct running-in of the new bulk cement tanker trailer has a great use for extending the lifespan and give full play to the function and economy of the trailers. The run-in period of a new bulk cement tanker trailer is 1000km. During the run-in period, the bulk cement tanker trailer should reduce the payload (Payload not over the half of Max.) and driving in limited speed.

2. Preparations before using the bulk cement tanker trailer

2.1. Check the fastening situation of each connect parts, especially notice the connect parts on Steering, braking, suspension, wheels and kingpin

2.2. Check the brake system if is normal and the pipeline if leakage air

2.3. Check the pressure of tires if meet the regulation.

2.4. Check the lighting system (turning light, brake light and taillight) if is working in normal

3. Operation guide of bulk cement tanker trailer

3.1 How to load bulk cement into pneumatic cement tanker trailer?

3.1.1. Drive the bulk cement tanker trailer under the bulk powder silo and open the pressure relief valve.

3.1.2. Open the manhole cover after exhausting. Make sure the feed opening align with the manhole, close the other valves and start Loading (Never open the cover under pressure).

3.1.3. Load the bulk cement on rated tonnage. Close and lock the manhole cover after cleaning the powder around the manhole.

3.1.4. Clean the powder on working platform. Close the Pressure relief valve.

3.2 How to unload bulk cement from pneumatic cement tanker trailer?

3.2.1. Connect the discharge pipe to inlet of bulk cement tanker

3.2.2. Check the ball valve, pressure relief valve, external air connector, discharge butterfly valve if is closed.

3.2.3. Open the Intake valve of bulk cement tanker, start the engine to drive the PTO and air compressor and filling the air into tank. Adjust the Hand Throttle to make tachometer read on 900r/min

3.2.4. In addition, the cement tanker also can be filled through an external air source.

3.2.5. Open the ball valve when the read of discharge pressure meter meets the requirements then open the discharge butterfly valve to unload the bulk cement.

3.2.6. When the tanker pressures reduce to the 10% of working pressure, the unloading can be finished. Relax the hand throttle and unbutton the PTO

3.2.7. Close the discharge butterfly valve, open the pressure relief valve

3.3 Some precautions for operate the bulk cement tanker trailer

3.3.1. You should open the pressure relief valve to ensure there are not pressures inside the tanker before open the manhole cover. Very important!

3.3.2. Do not let the debris, block etc. enter the tanker when loading to avoid the discharge pipe blocked

3.3.3. During pressure filling and unloading, pay attention to the working condition of the discharge barometer at any time. The pressure must not exceed the specified value. The working of safety valve must reliable and sensitive

3.3.4. After finished unloading, you should close the manhole cover and discharge valve. There must not air inside the tanker during transportation.

3.3.5. During unloading progress, if the rise of pressure exceeds specified value and makes the safety valve work, you should open the ball valve repeatedly to dredge the pipe and reduce the pressure.

If the pressure still in rising, you should stop and check the engine at once.

3.3.6. The rotating speed of the air compressor should be controlled at 850-1000 rpm

3.3.7. The semi-trailer should be started driving steadily. Do not sudden braking and acceleration during driving

3.3.8. Do not drive the trailer before the air system pressure reaches to rated safe pressure 450Kpa

3.3.9. When the disconnection switch of the inflatable pipe is cut off, the trailer will generate an emergency brake, which can be used in conjunction with the hand brake to enhance the ability to stand on the slope and used for temporary parking.

3.3.10. It is normal condition for a small amount of gas to escape from the exhaust port before the emergency relay valve stop work (pressure of the inflation pipeline 300Kpa ~ 450Kpa).

3.3.11. Every day when you stop working, you should discharge the residual water and oil inside the air cylinder with compressed air to avoid water accumulating, rusting, and oil scales in the brake pipeline, which will cause the brake failure

3.3.12. It is strictly forbidden to stand behind the tractor truck cabin when the semi-trailer is driving to avoid danger when turning or reversing

4. How to maintain the bulk cement tanker trailer?

4.1. Maintain tips on bulk cement tanker semi-trailer

4.1.1. Check and tighten each bolt and nut on bulk cement tanker trailer.

4.1.2. Fill the lubricating grease on fifth wheel, landing gear, Balance arm axle, rims etc.

4.1.3. Check and adjust brake clearance

4.1.4.When the bulk cement tanker trailer on heavy load, tighten the U-bolt with a torque of 490N.m ~ 590N.m.

4.1.5. Check and tighten bolts of the brake plate on tightening torque 70N.m ~ 80N.m

4.1.6. When the mileage of bulk cement tanker trailer reaches 12,000 kilometers, maintain and adjust the tires.

4.1.7. To keep the tanker body clean. After each work finished, Wash the dirt on outside of bulk cement tanker. Do not let the water splash into inside of tanker and discharge pipe

4.1.8. Check the connect pipe of bulk cement tanker trailer if leaks or abnormal regularly, repair immediately if any occur.

4.1.9. Check each operation handle if flexible and reliable

4.2. Maintain tips on air compressor

Please follow the use and maintain guide of air compressor

5. Common problems and solve methods when using bulk cement tanker trailers

|

Problems |

Reason |

How to solve |

|

1. When the pressure of the gas cylinder over than 490 Kpa .During gas filled, Gas escape from lower exhaust port |

Intake valve abrasion |

Smooth the rubber layer of the intake valve, then add a compensation gasket thickness 0.5-1mm between the exhaust valve and the relay piston |

|

Intake valve broken |

Change new parts |

|

|

Dirt stuck in the emergency piston valve. |

Clean and remove the dirt |

|

|

The O-ring seal of the Emergency valve gas cylinder cavity worn too much. |

Change new parts |

|

|

2. When braking, there is air escape from the lower exhaust port. |

Intake valve broken or has dirt |

Clean, recovery and add compensation gasket or change new parts. |

|

Relay piston stuck |

Clean and add grease |

|

|

3. When the brake control air source disappears, the brake chamber still has a certain pressure. |

Air pressure of gas cylinder too low |

Wait until the semi-trailer inflation pressure rises more than 441Kpa (4.5kgf / cm2) |

|

Relay piston stuck |

Clean and add grease |

|

|

4. Emergency braking cannot be performed after the inflation pipe is deflated. |

Emergency piston stuck |

Clean, add grease and remove dirt |

|

Check valve leak |

Clean or change new parts(Check valve and return spring) |

|

|

5. rear tires wear heavily |

Rear axle move |

Adjust the size of left and right tie rods and tighten U-bolts |

|

6. air supply device has shock and abnormal noise |

Bolts of transmission shaft loosen |

Fasten the bolts |

|

Fixing bolts of air compressor loosen |

||

|

7. Tank leakage |

Manhole cover no tightly closed |

Close the manhole tightly |

|

Valve no close tightly |

Close the valve |

|

|

8. Unloading time too long |

Insufficient air pressure or flow |

Maintain air compressor and exclude pipeline leakage |

|

Discharge pipe blocked |

Remove blockages |

|

|

Bolts of breathable fabric loosen |

Fasten the bolts |

|

|

Position of Bell mouth too high |

Adjust position |

|

|

9. Residual rate too high |

breathable fabric Ageing or damaged |

Change breathable fabric |

|

Insufficient air pressure |

Check and exclude reason |

|

|

Bulk Tanker tilted severely when unloading |

Keep the tanker horizontal when unloading |

|

|

Position of Bell mouth too high |

Adjust position |

|

|

Air compressor exhaust volume drops severely |

Maintain and change new parts |

|

|

10. Overpressure |

Discharge butterfly valve and discharge pipe blocked |

Stop machine and exclude reason |

Conclusion

Hope this article can help you better understand about maintain and operation of bulk cement trailer.

whether you choose to buy a new or used bulk cement tanker trailer, it is very import to confirmed the volume you want to use the bulker trailer to carry. Compare to a used bulk cement trailer, a new bulk cement trailer have better performance and lower maintain cost. In long terms, it is more cost-effective to operation new bulk cement trailers fleet.

If you have any advices or problems on the bulk cement trailer,welcome to write a message to us.